End of year holidays are coming soon. We look forward to sunny days, rest, relaxation, and fun. Whether your idea of fun is having a good sleep in, feasting with friends and family, catching up on physical fitness or a combination of all the above, enjoy! This is the time to refresh yourself so that you start the new year replenished and ready to go.

It’s normal as the year ends to recall the milestones experienced during the past year – both happy and sad – and to learn from them, as we move forward to greet the new year. Do you make New Years’ resolutions? We sure do.

Here are our 2 main resolutions.

Resolution #1

You guessed it. But you can’t say we didn’t give you a clue. However, in case you didn’t, here it is.

Every. Kiwi. Home. Safe. Every. Day.

Boring? Yes. But that’s how we like it. In fact we like it so much that we’ve been working on keeping things safe since 1997.

Resolution #2

Protecting your assets.

Not as important as Resolution #1, but still key to everyone’s well-being. Damaged facilities and machinery don’t make for happy and successful businesses or people.

Now to follow those safety resolutions through.

Back in April of this year, we posted a blog called ‘16 Workplace Hazards, and 3 Steps to Safety’.

The 3 steps to safety include

1. Identifying hazards. Know what the dangers are in an industrial environment and look out for them.

2. Do a job hazard analysis as in ‘Find the accident that is waiting to happen.’

3. Take measures to eradicate or lower the risks. (We really want to eradicate them.)

New Zealand’s labour force

Almost 2 million Kiwis make up New Zealand’s labour force. Of these 2 million, 20.7% or more than 400,000 people are employed in industry – mining, manufacturing, energy production, and construction. Another 72.7% work in services –government activities, communications, transportation, finance, and all other economic activities that do not produce material goods. Agriculture accounts for 6.6% of the workforce.

Machinery and people.

Services and agriculture present their own dangers, but our focus in this article is on the 400,000 people employed in industry. Every day, they head off to work, put their time in and come home again.

But sometimes it doesn’t work like that. And that’s what we want to change.

A simple fact of life in industry is that you have machinery and people. Machines, by definition, amplify power. This means that the smallest power-driven tool can cause human injury. So even though we, as people, control the machinery, the potential for injury is always there.

Every machine has a danger zone

We all know that forklifts, tractors, and other rolling stock is a danger to pedestrians. But how about that parked truck waiting to be unloaded? Or the automatic bandsaw on the shop floor? And the automated press in your factory? That’s where we insist on an ‘enforced exclusion zone’.

But, we agree, it’s not always practical to have permanent barriers in place.

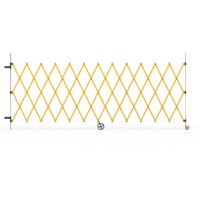

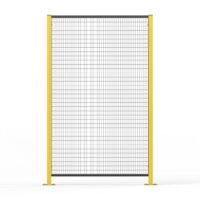

Enter SpanSafe, the expandable barrier system

Spansafe is a happy minion that fits in with whatever you need to do.

You need to cordon off a dangerous area? No problem.

Poles are simply attached to the wall with supplied brackets. Pull out the expandable barrier, latch it at the other end, and block interaction between rolling stock and people. 3 heights plus multiple widths makes it a cinch.

Want your space open again? Go for it.

The SpanSafe System is designed for flexibility. The barrier folds back, and pivots out of the way when not in use.

See more about SpanSafe in this video: https://dexters.wistia.com/medias/rhqpu1uruz

An installed, ready-to-go safety system will get used.

When safety precautions are a hassle to put in place, it’s tempting not to bother. So take a look around your shop, factory or warehouse, and see where SpanSafe should be installed. In doorways, around machinery, temporary walkways, and of course, loading and unloading zones. You’ll get more mileage from your space, but, more importantly, you can relax, knowing that you and your workers are safe.